Gearless Elevator Traction Machines: Modern PMSM Solutions #

The Gearless Permanent Magnet Synchronous Motor (PMSM) Elevator Traction Machine represents a significant advancement in elevator technology. Designed for efficiency, safety, and comfort, this machine integrates a permanent-magnet synchronous motor, traction wheel, and brake system, all managed through an encoder for precise closed-loop and frequency control operations.

Key Features #

-

High Efficiency & Performance

The PMSM gearless traction machine boasts a high efficiency factor, minimal starting current, and substantial starting torque. Its gearless design ensures smooth, comfortable operation, reduced noise, and high reliability. -

Compact & Lightweight

Utilizing rare earth permanent magnet materials, the machine is compact and lightweight, making it suitable for a variety of installation environments. -

Low Noise & Environmental Considerations

The motor operates at noise levels less than or equal to 60dB. Non-asbestos brake linings and stable performance across various working conditions further enhance its environmental credentials. -

Safety & Comfort

Advanced field-oriented control improves ride comfort and floor leveling accuracy, ensuring passengers experience smooth and pleasant journeys. -

Natural Cooling

The machine is designed for natural cooling, supporting reliable operation without the need for additional cooling systems.

Construction and Components #

- Motor Housing: Crafted from gray cast iron (FC25), the housing delivers excellent vibration absorption and durability.

- Encoder: Pre-installed interfaces on the motor shaft allow for flexible configuration options.

- Safety Handle Wheel: Enables manual operation to safely stop the elevator at the nearest floor during power outages.

- Wire Rope Wheel: Made from spherical graphite cast iron (FCD650) with hardness HB230~260 for longevity.

- Manual Brake Release: Allows controlled release of the brake for safe car positioning during power loss.

- Electromagnetic Brake: Rated for over 1 million operations with noise levels below 60dB.

- Safety Cover: Protects against accidental damage during wire rope operation.

- Structural Elements: Features cold silicon steel stator (F class insulation), NdFeB permanent magnets, self-aligning roller bearings, and a QT-700 nodular graphite cast iron traction wheel.

Operating Conditions #

The gearless PMSM traction machine is designed to meet the requirements of GB/T 13435-1PPZ “elevator traction machine” standards, with the following environmental parameters:

- Indoor temperature: 5 ~ 40°C

- Maximum monthly average relative humidity: < 90% (minimum temperature not higher than 25°C)

- Supply voltage fluctuation: within ±7% of rated value

- No corrosive or flammable gases in the ambient atmosphere

- Traction ropes must be clean, free of lubricants or contaminants

- Compliance with GB / T 7588-2003 (Article 9.3.1b) for cargo/counterweight and rope angle

Noise and Vibration #

- Electrical Noise: ≤ 60dB

- Vibration Velocity RMS: 1mm/s and below

- Vibration Acceleration: 2m/s² and below

- Pulley Torsion Vibration: 4.5mm/s and below

- Amplitude: 15µm and below

Product Specifications #

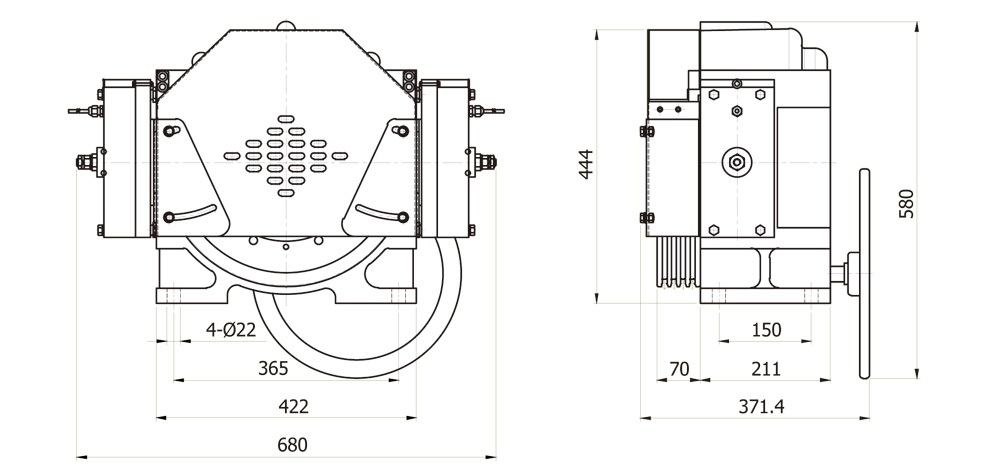

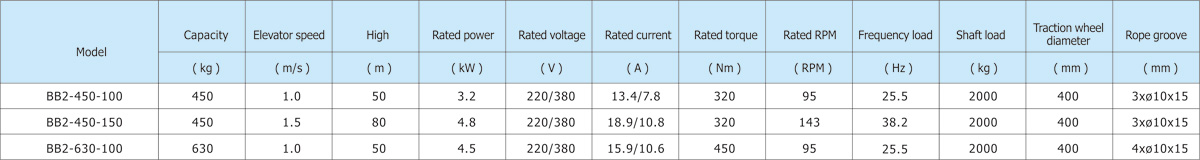

360 Series #

- Structure: Internal Rotation

- Suspension: 2:1

- Brake Voltage: DC110V

- Operation ED: 60% ED

- Insulation Class: F class

- Weight: 240 kg

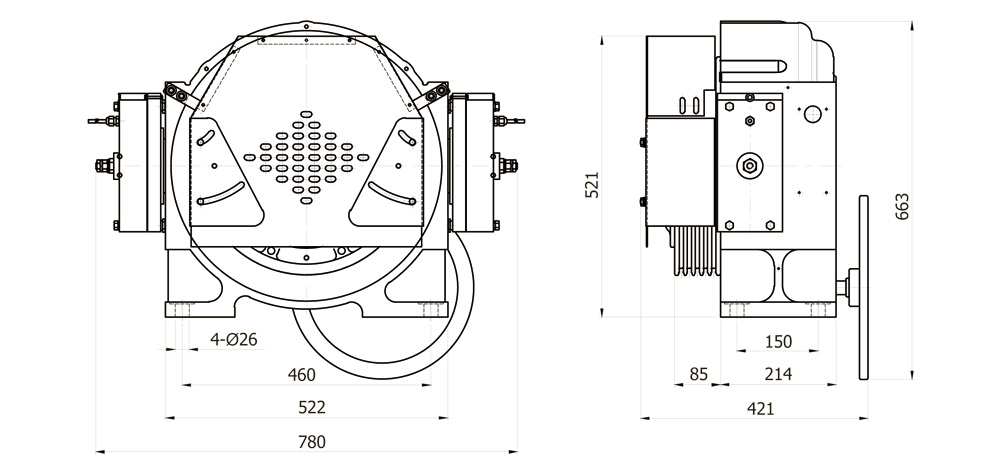

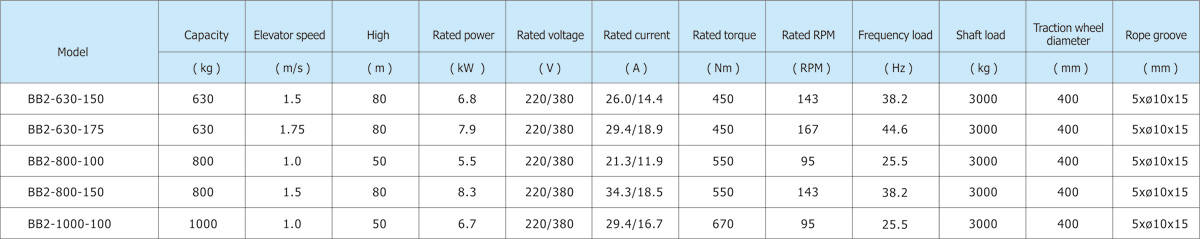

460 Series #

- Structure: Internal Rotation

- Suspension: 2:1

- Brake Voltage: DC110V

- Operation ED: 60% ED

- Insulation Class: F class

- Weight: 320 kg

560 Series #

- Structure: Internal Rotation

- Suspension: 2:1

- Brake Voltage: DC110V

- Operation ED: 60% ED

- Insulation Class: F class

- Weight: 410 kg

No : BB2 - Gearless Permanent Magnet Synchronous Motor Elevator Traction Machine

No : BB2 - Gearless Permanent Magnet Synchronous Motor Elevator Traction Machine

Gearless P.M.S.M Traction Machine 360

Gearless P.M.S.M Traction Machine 360

Gearless P.M.S.M Traction Machine 360

Gearless P.M.S.M Traction Machine 360

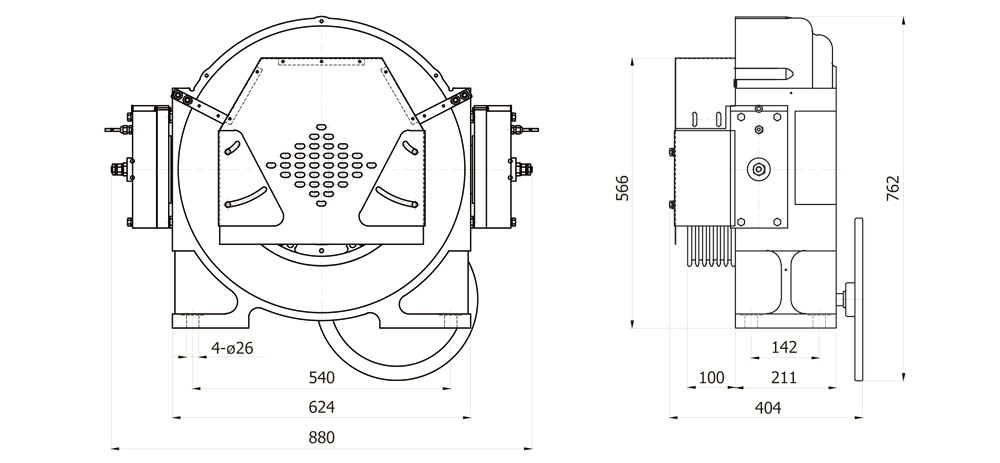

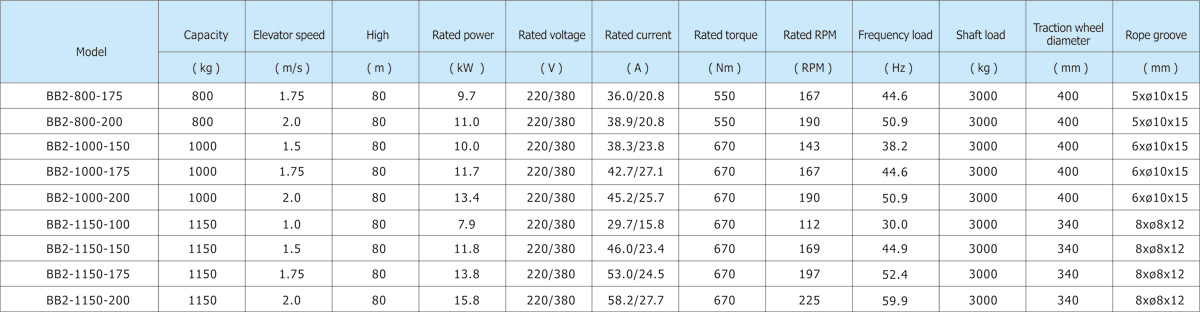

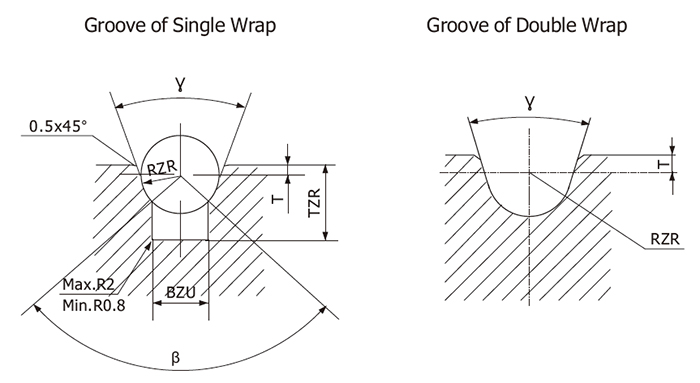

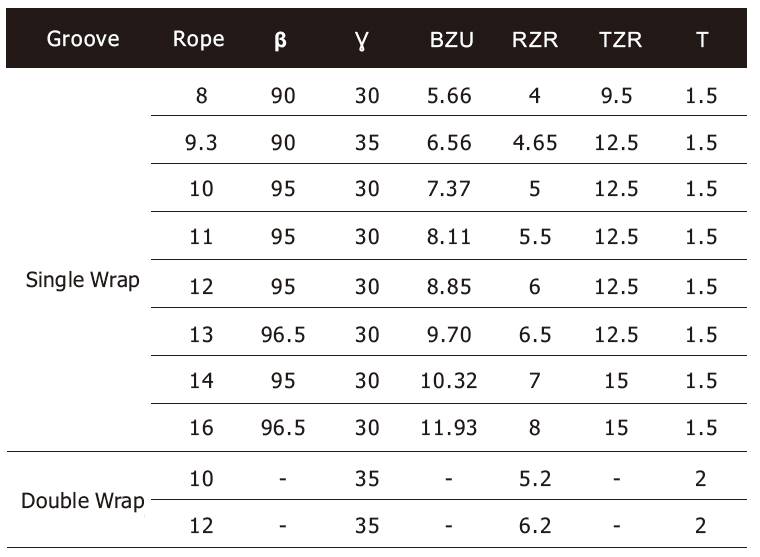

BB2 Gearless P.M.S.M Traction Machine 460

BB2 Gearless P.M.S.M Traction Machine 460

BB2 Gearless P.M.S.M Traction Machine 460

BB2 Gearless P.M.S.M Traction Machine 460

BB2 Gearless P.M.S.M Traction Machine 560

BB2 Gearless P.M.S.M Traction Machine 560

BB2 Gearless P.M.S.M Traction Machine 560

BB2 Gearless P.M.S.M Traction Machine 560

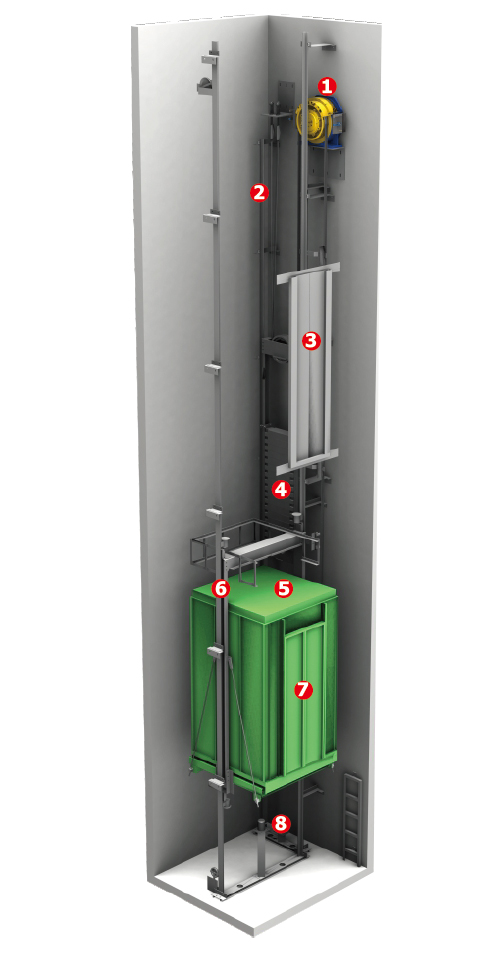

Elevator Shaft

Elevator Shaft

Elevator Shaft

Elevator Shaft

Elevator Shaft

Elevator Shaft

Installation and Application #

- Mounting: Foot mount installation

- Power Supply: Inverter input

- Maximum Rated Torque: 200%

- Operation ED: 60% ED

- Insulation Class: F Class

- Location: Indoor

- Temperature Range: -10 ~ +40°C

- Humidity: Up to 90% RH (no frost)

- Altitude: Up to 1000m

- Encoder Options: 2048/8192 P/R (optional)

- Brake: Dual Electromagnetic Brake

- Suspension: 2:1

Elevator Shaft Components #

- Traction Machine

- Counterweight Rail Guide

- Service Door (outside)

- Counterweight

- Car Cage

- Car Rail Guide

- Car Door (inside)

- Buffer

Note: Data and configurations are subject to change without prior notice. Users should calculate the elevator traction capability and rope safety factor based on actual parameters.